Eco-design of advanced biomaterials

The polymers developed by the POLYBIO group are used for the sustainable production of advanced biomaterials based on bioplastics, with properties that can be tailored according to the specific need of each application. These biomaterials are designed according to sustainability criteria, taking into account both their functionality and possible strategies for their end-of-life management. According to their composition, these materials can be classified in three groups:

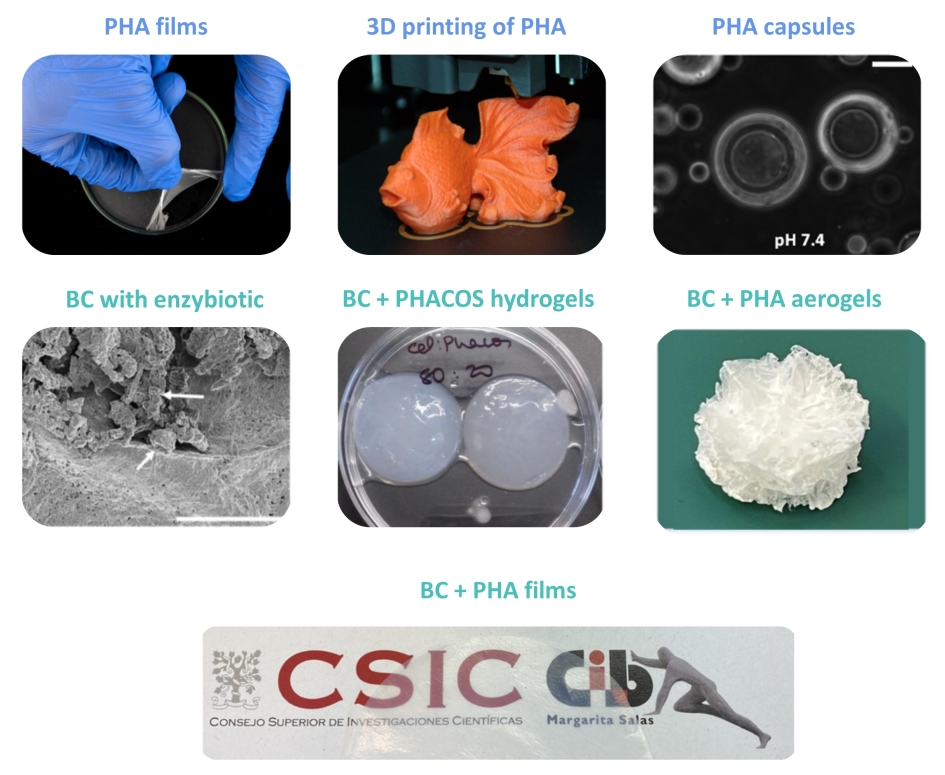

1) PHA-based biomaterials: The hydrophobicity of PHA, as well as their simple thermoforming, make these bacterial polyesters an ideal bio-based solution to replace petrochemical plastics. In the POLYBIO group we produce PHA-based materials of different nature: polyesters with varying side chain length and antimicrobial PHA (PHACOS). We use different processing strategies for PHA, including solvent casting, extrusion, and 3D printing, which allow their application in sectors such as packaging, agriculture, and others. Additionally, we develop nano- and microparticles, as well as capsules, designed for pulmonary drug delivery or the controlled release of living antimicrobial agents. We also explore the use of PHA granule-binding proteins (phasins) as interface stabilizing agents in aqueous media and for the immobilization of different components on the polyester surface. Lastly, we investigate the fabrication of materials with programmed biodegradation to guarantee their controlled decomposition once they are accidentally or intentionally released into the environment due to their application (for example, in agriculture).

2) Cellulose-based biomaterials: The reticular structure of bacterial cellulose (BC), characterized by homogenous pores of 7-9 μm, enables its use as matrix to hold active compounds for different purposes. Some relevant applications include controlled drug delivery (e.g. enzybiotics and other antimicrobial agents), wound dressings with anti-inflammatory properties, synthetic leather, and other emerging sectors.

3) Composite bio-materials: The combination of PHA and BC presents certain challenges, mainly due to their different behavior towards water, which makes the formulation of stable composite materials difficult. In the POLYBIO group, we work on developing materials that take advantage of the beneficial properties of both polymers: the mechanical resistance and reticular structure of BC, and the barrier properties of PHA. In this way, we fabricate hydrogels, aerogels, and films with outstanding gas barrier properties or antimicrobial activity, making them suitable for applications such as packaging, biomedicine, and functionalized containers. Likewise, we have developed particles capable of sustaining viable microorganisms during extended periods of time.

Relevant publications:

Hernández‐Arriaga, A. M., Campano, C., Rivero‐Buceta, V., & Prieto, M. A. (2022). When microbial biotechnology meets material engineering. Microbial Biotechnology, 15(1), 149-163.

Blanco, F. G., Vázquez, R., Hernández-Arriaga, A. M., García, P., & Prieto, M. A. (2023). Enzybiotic-mediated antimicrobial functionalization of polyhydroxyalkanoates. Frontiers in Bioengineering and Biotechnology, 11, 1220336.

Campano, C., Rivero-Buceta, V., Fabra, M. J., & Prieto, M. A. (2022). Gaining control of bacterial cellulose colonization by polyhydroxyalkanoate-producing microorganisms to develop bioplasticized ultrathin films. International Journal of Biological Macromolecules, 223, 1495-1505.